Web Menu

Product Search

Exit Menu

We provide quality products and services to customers from all over the world.

Why Is Quality Inspection Essential at Every Level for Water Resistant Boob Tape?

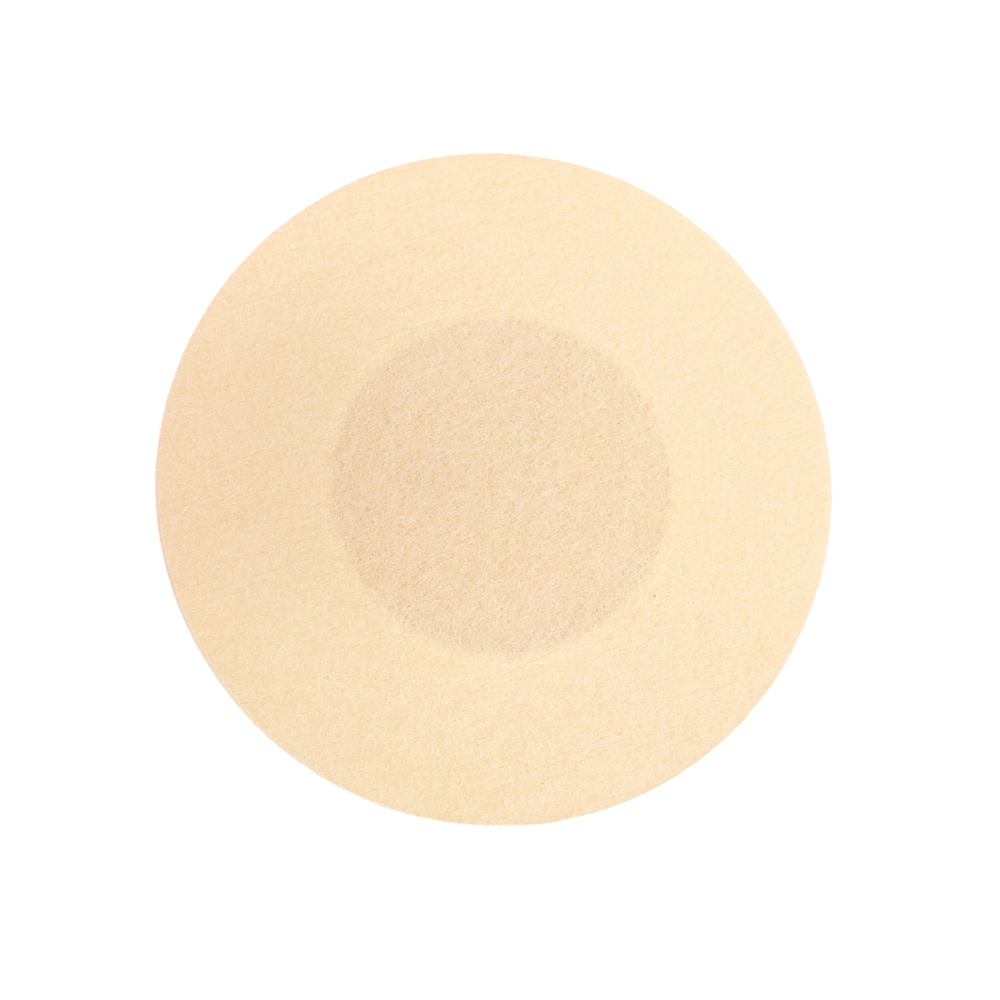

Water resistant boob tape is widely used for fashion, special occasions, and active wear, offering a flexible, strapless alternative to traditional bras. Because this product adheres directly to sensitive areas of the skin, particularly around the chest and shoulders, thorough quality inspection at every production stage is essential. Quality control not only affects product performance, but also has direct implications for skin safety, user comfort, and consumer trust.

At the material sourcing stage, the inspection focuses on selecting skin-safe adhesives and fabrics. Manufacturers typically use medical-grade acrylic adhesives that provide strong yet gentle sticking power. These adhesives must be tested for hypoallergenic properties and consistent tackiness to ensure they adhere well without causing irritation. The backing material—usually cotton, nylon, or a synthetic blend—must also be evaluated for flexibility, breathability, and water resistance. If any of these components do not meet regulatory or internal safety standards, the tape may fail to perform reliably or cause discomfort.

During the manufacturing phase, automated systems and manual checks are used to monitor tape thickness, edge trimming, roll consistency, and adhesive distribution. For water-resistant products, additional layers or treatments are often applied to improve moisture resistance. These must be evenly applied to prevent peeling or bunching when exposed to sweat or water. Each batch is typically subjected to water immersion or simulated wear tests to confirm resistance levels under real-world conditions.

Pre-shipment inspection includes packaging integrity, expiration labeling, and sample use tests. A properly labeled and sealed package ensures that users receive a product that maintains its stickiness and cleanliness, even after storage or shipping.

For individuals with sensitive skin, using adhesive tape products—especially around delicate areas like the chest—can concerns about irritation, redness, or even allergic reactions. Sensitive skin athletic breasts tape is specifically designed to minimize these risks by using carefully selected materials and skin-friendly formulations.

The primary factor in allergy prevention lies in the type of adhesive used. Many sensitive skin tapes utilize medical-grade acrylic adhesives, which are known for being both strong and hypoallergenic. Unlike rubber-based or synthetic adhesives found in some general-purpose tapes, acrylic adhesives are water-based and contain fewer sensitizing agents. They are designed to adhere well without deeply penetrating the skin, thus reducing the risk of triggering a skin response.

In addition, the backing fabric is typically made from soft, breathable materials such as cotton or a cotton-polyester blend. These fabrics allow air to circulate and help wick moisture away from the skin, reducing the buildup of sweat and friction—two common contributors to skin irritation. Breathability is especially important for use during physical activity, where heat and moisture levels are elevated.

Another crucial aspect is the skin preparation process. Many sensitive skin tapes are accompanied by usage guidelines that recommend applying to clean, dry skin and avoiding areas with cuts, irritation, or sunburn. Some products may even include a sample strip or suggest a patch test, allowing users to try the tape on a small area before full application. This step can help identify any individual sensitivities without the risk of widespread reaction.

Many sensitive skin breast tapes are latex-free and free from added fragrances or dyes, which are common allergens. This formulation makes them safer for people with known contact allergies.

Keep In Touch

No.455 New Town Development Road,Longgang City, Wenzhou City

Copyright © Wenzhou Anqi Medical Supplies Co., Ltd. All Rights Reserved.

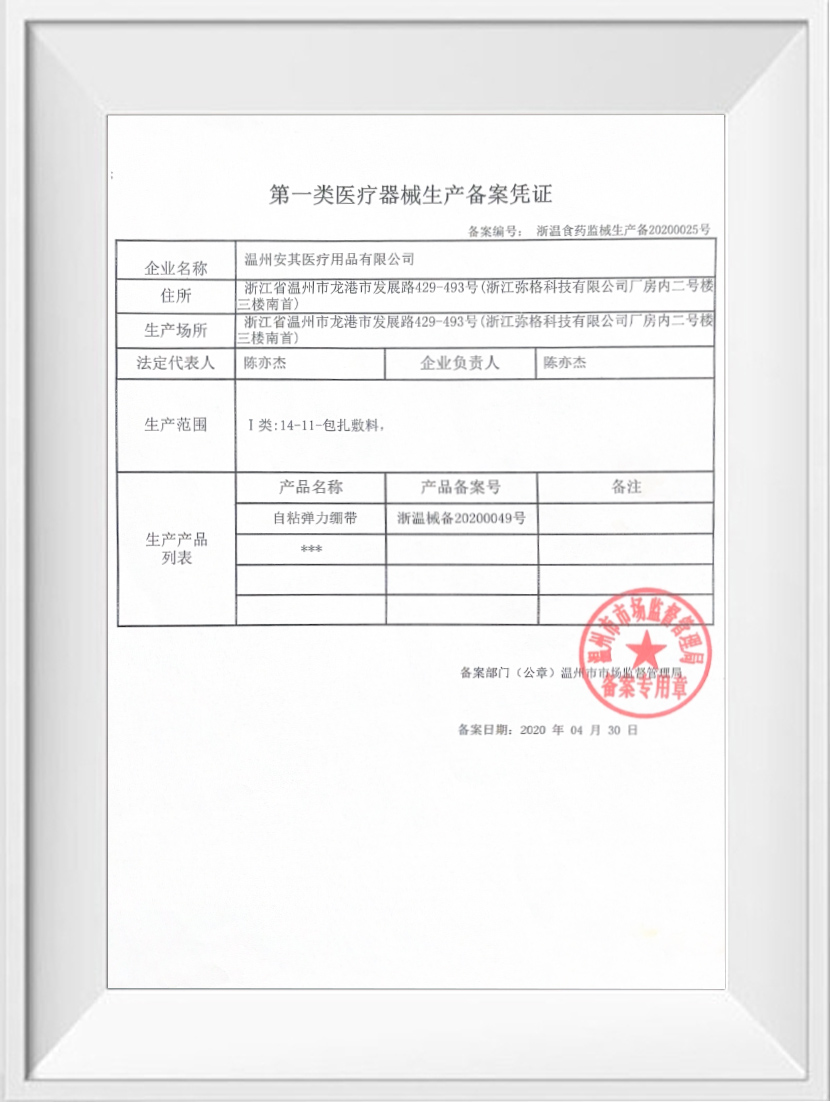

Approval No: Zhejiang Wenzhou Food and Drug Administration Machinery Production Filing No. 20200025

The information provided on this website is intended for use only in countries and jurisdictions outside of the People's Republic of China.

English

English русский

русский 中文简体

中文简体 Español

Español Deutsch

Deutsch عربى

عربى