Web Menu

Product Search

Exit Menu

We provide quality products and services to customers from all over the world.

How to Buy Self Stick Compression Waterproof Sports Wrap

When it comes to injury prevention and rehabilitation, few products are as essential as self-stick compression wraps and elastic bandage wraps. They are indispensable tools in the sports world, used to stabilize injuries, reduce swelling, and provide effective support to vulnerable joints and muscles. Whether you're recovering from a sprain or simply want to prevent injury during physical activity, these products are designed to keep you moving comfortably.

Self Stick Compression Waterproof Sports Wrap is a popular product used by athletes and active individuals alike. Whether you're dealing with an injury or simply looking to prevent one, this type of wrap can be incredibly useful. Here's how to go about buying one that meets your needs.

Key Features to Consider:

Compression Level: When purchasing a self-stick compression wrap, the thing to consider is the level of compression it provides. Compression wraps are designed to provide varying levels of support, and the level you choose should depend on the nature of your injury or the area that needs protection. A higher compression level is often needed for injuries involving swelling, while moderate compression might suffice for injury prevention or mild support.

Waterproof Properties: For athletes who train outdoors or engage in water-based sports, waterproof compression wraps are essential. These wraps are designed to stay in place even when exposed to sweat or moisture, ensuring that they maintain their grip and effectiveness during intense activities. If you are active in such environments, choosing a waterproof option will be key to ensuring comfort and long-lasting performance.

Elasticity and Comfort: A good sports wrap should be both flexible and comfortable, providing adequate support without restricting movement. Look for wraps made with high-quality elastic materials that stretch easily and conform to the contours of your body. The wrap should provide support to the area without causing discomfort or cutting off circulation.

Self-adhesive elastic bandage wraps are a staple in medical and sports settings, offering convenience, flexibility, and stability. The process of producing these wraps is highly technical, involving specialized machinery that ensures the product's quality, elasticity, and adhesive properties. Here's an overview of the key machinery involved in manufacturing self-adhesive elastic bandage wraps.

The step in the production process involves weaving the fabric for the bandage. Textile weaving machines are used to create the base material, typically made from cotton, polyester, or a combination of fibers. The machines interlace the yarns into a fabric that is both flexible and durable. The key here is achieving the right balance between stretch and strength.

The fabric is woven with a particular elasticity to ensure that the bandage can stretch and conform to the body without losing its structural integrity. The weaving process also determines the thickness and texture of the fabric, which will influence the comfort and compression properties of the final product.

Once the fabric is prepared, it moves to the next stage—adhesive coating. Self-adhesive bandages require a layer of adhesive to ensure they stick to the skin or themselves. The adhesive is typically made of medical-grade materials like zinc oxide or acrylate compounds that are skin-safe and effective at maintaining the bandage's position during physical activity.

Coating machines are used to evenly apply the adhesive to the fabric. The adhesive is typically applied to one side of the fabric, and the machine ensures that it is uniformly distributed across the surface. Depending on the type of bandage, some machines can apply an additional layer to make the bandage either more or less sticky. The application process needs to be precise to ensure consistent performance throughout the length of the wrap.

Keep In Touch

No.455 New Town Development Road,Longgang City, Wenzhou City

Copyright © Wenzhou Anqi Medical Supplies Co., Ltd. All Rights Reserved.

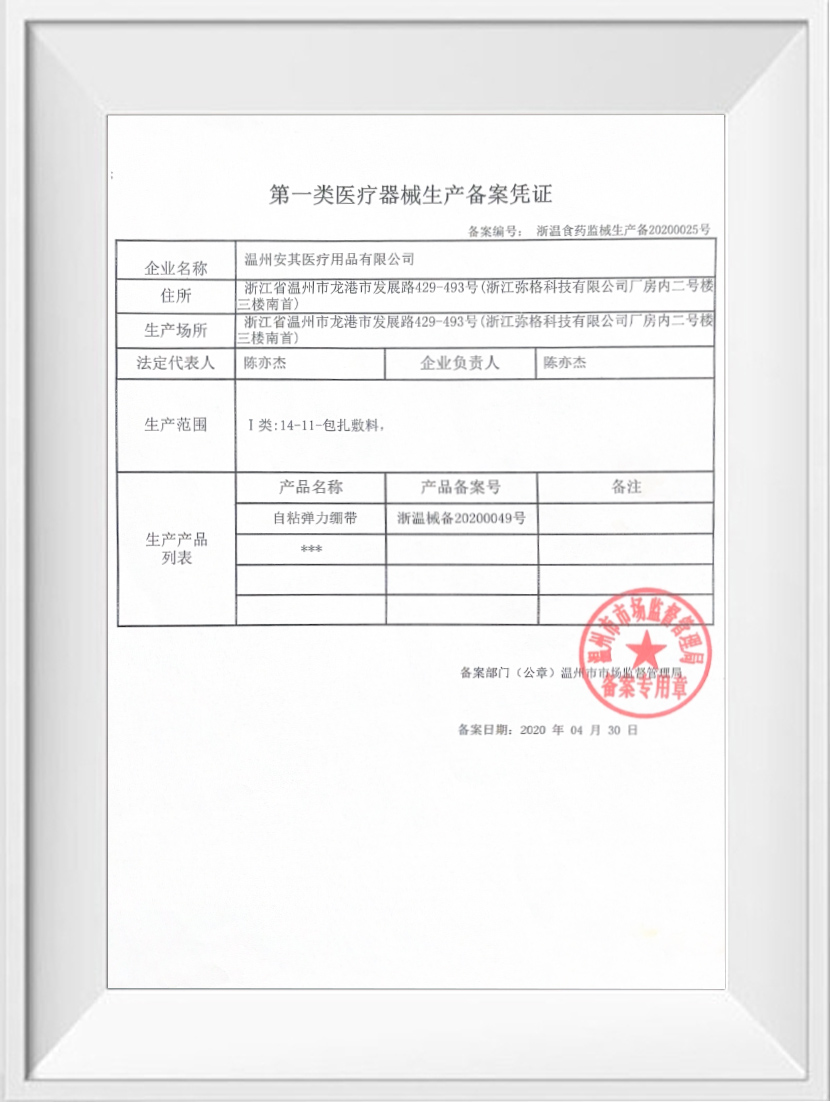

Approval No: Zhejiang Wenzhou Food and Drug Administration Machinery Production Filing No. 20200025

The information provided on this website is intended for use only in countries and jurisdictions outside of the People's Republic of China.

English

English русский

русский 中文简体

中文简体 Español

Español Deutsch

Deutsch عربى

عربى