Web Menu

Product Search

Exit Menu

We provide quality products and services to customers from all over the world.

From Factory to Field: Athletic Pain Relief Tape Production

As sports science continues to evolve, so does the technology behind supportive and therapeutic tools used by athletes and healthcare professionals. Among these tools, Athletic Pain Relief Tape and Medical Stretch Tape for Muscle Strain have become essential items in both competitive and rehabilitation settings. Understanding how these products are made and how they compare across brands and types helps users make more informed decisions, whether they're athletes, trainers, or general consumers.

The production of Athletic Pain Relief Tape involves a combination of material science, manufacturing precision, and quality assurance to ensure the tape delivers both support and therapeutic function.

The process begins with material selection. The core material is typically a cotton or synthetic fabric that provides flexibility and breathability. Cotton is favored for its comfort and skin-friendliness, while synthetic materials like polyester or nylon offer durability and moisture resistance. A key feature of the tape is its elasticity—usually designed to stretch up to 140%–180% of its original length to mimic the skin's natural movement.

Once the fabric is selected, a medical-grade adhesive is applied to one side. This adhesive is pressure-sensitive and typically hypoallergenic, allowing it to stick to the skin without causing significant irritation. The application is done in a pattern—often in wave or grid formations—to allow for better skin ventilation and adherence under motion and sweat.

After adhesive application, the tape goes through a curing and drying phase, where it is heated to set the adhesive properties. It is then fed through cutting machines that slice the material into specific widths and lengths, commonly 5 cm x 5 m rolls. Some versions are pre-cut into strips for convenience.

Medical Stretch Tape for Muscle Strain is a broader category that includes kinesiology tapes, elastic therapeutic tapes, and supportive wraps designed to manage soft tissue discomfort and mild injuries. Comparing these tapes across different manufacturers and use cases provides valuable insight into their effectiveness and usability.

Different brands use varying base materials. Premium tapes often feature a cotton-spandex blend or high-performance synthetic fibers. For example, well-known brands such as KT Tape or RockTape use synthetic materials that dry quickly and resist fraying. Less expensive alternatives may use standard cotton and basic adhesive, which can affect durability and comfort.

In terms of adhesion, medical stretch tapes generally use acrylic-based adhesives. The quality of this adhesive impacts wear time and skin compatibility. While higher-end products can stay on the skin for 3–5 days, some budget-friendly versions may start peeling within a day, particularly in humid or sweaty conditions.

One of the defining features of Medical Stretch Tape for Muscle Strain is its elasticity. Many tapes aim for a stretch level close to that of human skin. However, not all tapes achieve consistent stretch tension. Tapes that lack uniform elasticity may not provide the desired therapeutic effect or may fail to stay in place during active movement.

Brands like SpiderTech or Kinesio offer pre-engineered strip designs tailored for specific body parts, enhancing ease of use and ensuring correct tension levels. Others come in uncut rolls, which allow for more customization but require user knowledge for proper application.

Keep In Touch

No.455 New Town Development Road,Longgang City, Wenzhou City

Copyright © Wenzhou Anqi Medical Supplies Co., Ltd. All Rights Reserved.

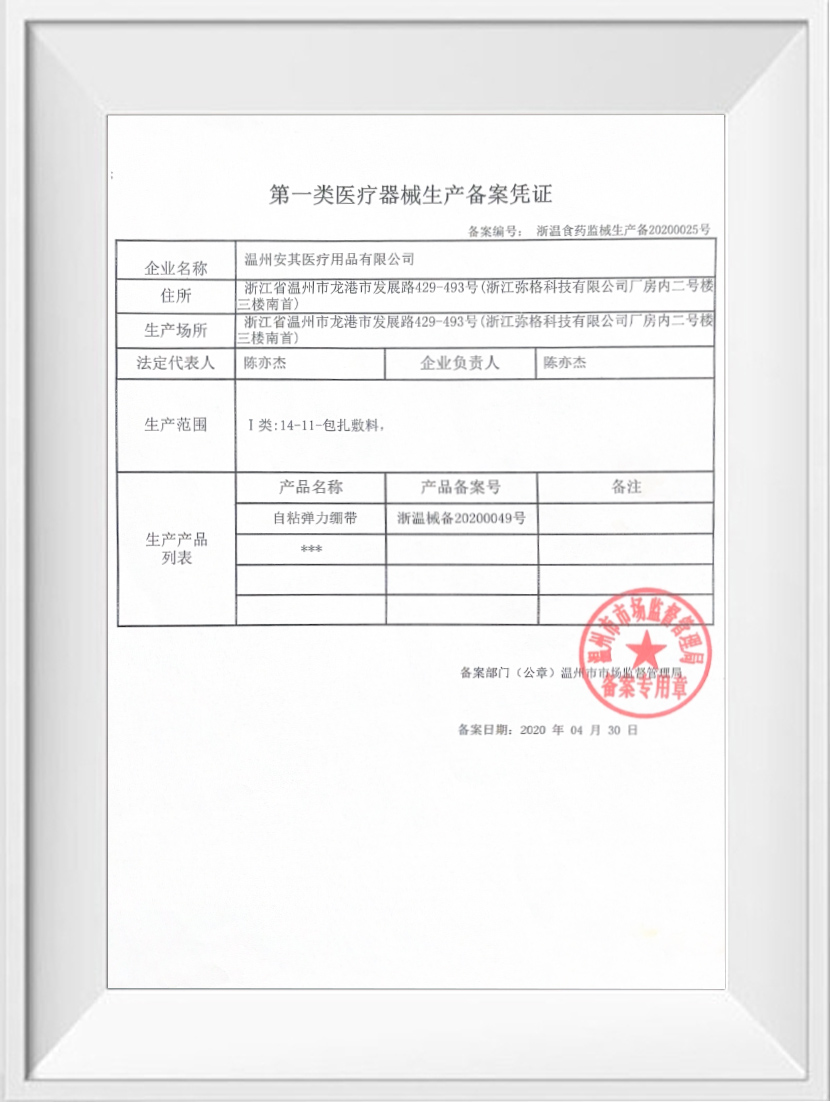

Approval No: Zhejiang Wenzhou Food and Drug Administration Machinery Production Filing No. 20200025

The information provided on this website is intended for use only in countries and jurisdictions outside of the People's Republic of China.

English

English русский

русский 中文简体

中文简体 Español

Español Deutsch

Deutsch عربى

عربى